Knowing When to Use Sensors for Robotic Welding

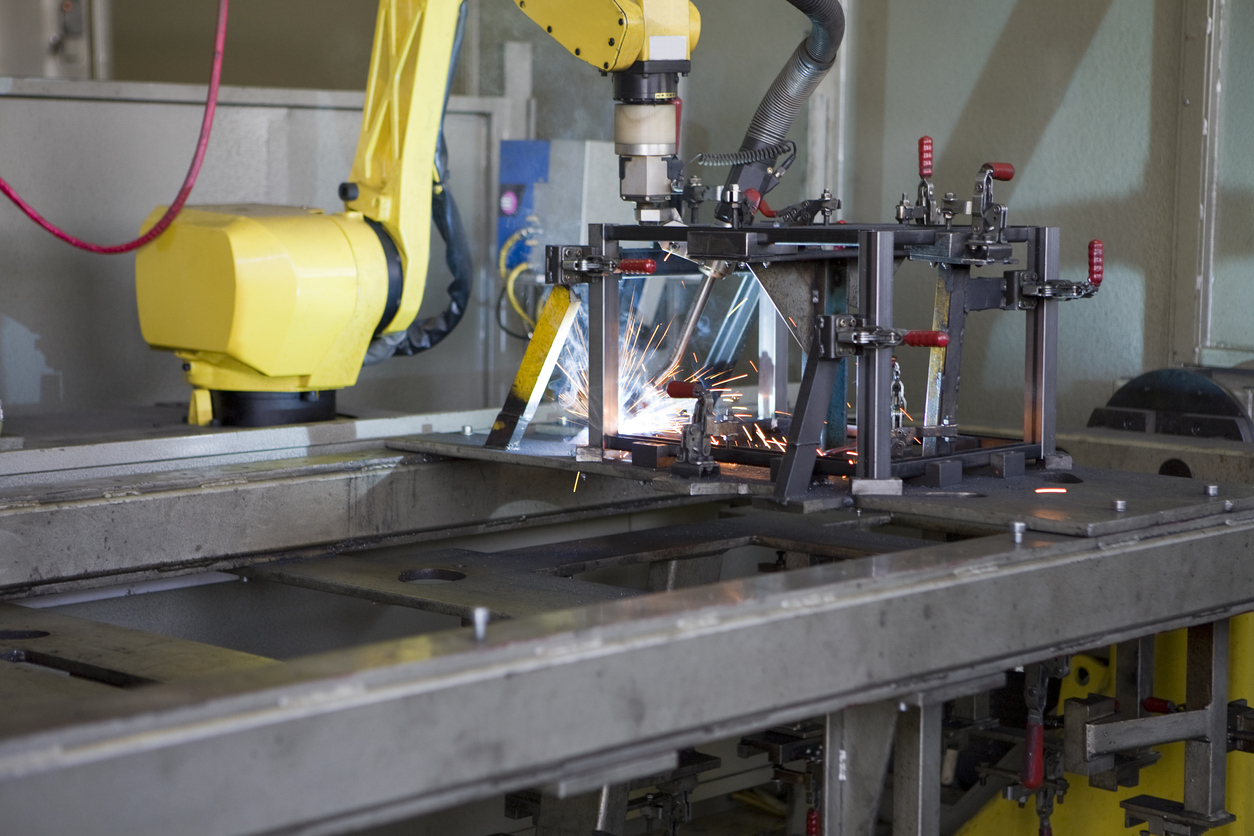

Robotic welding has revolutionized manufacturing by increasing efficiency, precision, and consistency. However, even the most advanced robotic systems can benefit from the addition of sensors, which provide real-time feedback and improve overall performance. By enhancing a robot’s ability to detect, adapt, and correct during the welding process, sensors can significantly boost productivity and reduce errors.

With so many sensor technologies available, it's important to understand when and how to implement them in your robotic welding setup. Choosing the right type of sensor depends on the complexity of the parts you're working with, the level of automation required, and the return on investment you expect. Let's explore some of the most common types of sensors used in robotic welding and when they make the most sense.

Types of Robotic Welding Sensors

As robotic welding has grown in popularity across various industries, different sensor technologies have been developed to address specific challenges. Here are some of the most commonly used sensors:

- Touch Sensors: These sensors are ideal for applications where physical contact is necessary. They work by making electrical contact between the welding nozzle and a pre-defined point on the part. This allows the robot to accurately locate the weld position and maintain high precision throughout the process.

- Seam Tracking with Arc Sensors: For arc welding robots, these sensors help ensure consistent and accurate welds. Positioned at the back of the system, they monitor the robot’s path and compare it to the programmed one. Any deviations in speed or position are automatically corrected, ensuring quality output.

- 2D and 3D Camera Sensors: Vision-based sensors are powerful tools for guiding robots to the correct welding location. Although welding environments can be challenging due to bright light and heat, these systems can quickly identify the target area, reducing errors and improving accuracy.

These sensors are just a few examples of how technology can enhance robotic welding operations. The key is to choose the right tool for your specific application.

When Does It Make Sense to Invest in Robotic Welding Sensors?

Sensors are most beneficial in situations where there is a high degree of variability in the parts being welded. If your production involves frequent changes in part design or complex shapes that are hard to align, sensors can provide the flexibility needed to maintain consistent results.

Additionally, if your current tooling or fixtures aren’t sufficient to handle variations in part positioning, investing in sensors may be the best solution. While the initial cost can be significant, the long-term benefits—such as reduced rework, fewer defects, and increased throughput—can make the investment worthwhile.

Before making a decision, it’s essential to evaluate the potential ROI. In cases where productivity improvements are substantial and the cost of errors is high, sensors can be a game-changer.

If you're looking to optimize your robotic welding system, consider consulting with experts who specialize in robotic integration. Companies like Genesis Systems have over 35 years of experience in designing and implementing highly efficient robotic welding solutions. Their expertise can help you determine the best approach for your unique needs.

Posted in Robotic WeldingPetrolatum Tape, also known as: grease anticorrosive oil tape, a kind of flexible oil ester fiber corrosion proof sealing oil belt suitable for wet, underwater environmental conditions. With mineral grease primer, mineral grease sealing putty, polymer adhesive tape used together to form a complete corrosion protection system.

Cold Applied Petrolatum Tape,Anticorrosive Wrap Petrolatum tape,Petrolatum Tape,Corrosion Protection Petrolatum tape,Marine Steel Pile Petrolatum Tape

JINING XUNDA PIPE COATING MATERIALS CO.,LTD , https://www.xundapipelinetape.com