In this article, we're taking a closer look at two types of stepper motors—high-resolution and encoder type—and how they can significantly enhance precision in critical laboratory automation systems like autosamplers.

|

Jump to sections:

|

Â

What is an autosampler?

Credit: Wikipedia

Â

An autosampler is an automated system that delivers samples to an analytical instrument for testing. These devices are commonly used in laboratory automation to handle large volumes of samples efficiently. They can collect samples from a central source and bring them to a sampling station or move the sampling equipment to the sample on a carousel. For example, in medical labs, autosamplers are used to test blood samples for diseases like viruses.

Positioning accuracy is crucial for these systems, which is why both servo and stepper motors are often used. Stepper motors offer precise control and accurate positioning, making them ideal for tasks like sample injection and syringe movement. For more complex applications requiring higher throughput, such as robotic arms, servo motors provide better torque and speed. However, for this article, we will focus on the advantages of using stepper motors.

Examples of Autosamplers

|

|

An autosampler for solid samples for gamma ray measurement |

|

Credit: Wikipedia |

Credit: Wikipedia |

Â

An autosampler requires high precision, so the motors must deliver consistent performance.

Â

A standard 2-phase hybrid stepper motor typically steps at 1.8°, with an open-loop stop accuracy of ±0.05° (±3 arc minutes). By improving the motor's positioning accuracy, the overall machine performance can be enhanced significantly.

Â

How do you improve the positioning precision of stepper motors?

You can boost positioning accuracy by either increasing the motor’s resolution or by adding an encoder (or both). In this article, we'll explore two types of stepper motors that help achieve this: high-resolution and encoder-type motors.

Â

|

Option 1

|

Use a high resolution type stepper motor to increase resolution and accuracy. |

Â

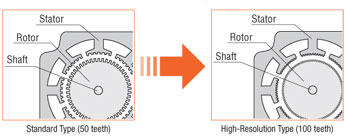

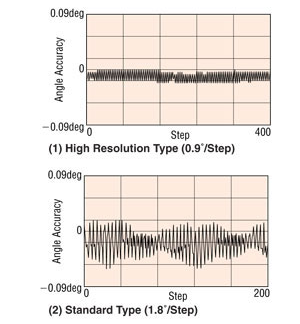

By replacing a standard 2-phase stepper motor with a high-resolution 2-phase motor, the motor’s resolution doubles due to a reduced tooth pitch—from 7.2° to 3.6° (360° divided by 50 or 100 teeth). This allows for finer steps, such as 0.9° instead of 1.8°, resulting in improved movement precision.

Â

|

In a high-resolution stepper motor, the number of rotor teeth has doubled to 100 compared to 50 in a standard motor. This reduces the tooth pitch and results in a basic step angle of 0.9°. |

|

|

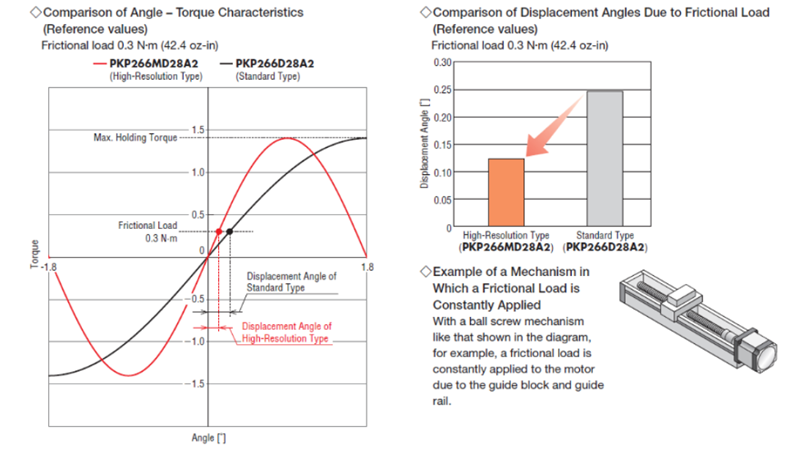

The high-resolution type increases the motor's resolution from 200 to 400 steps per revolution. Smaller step angles can be achieved through half-step or microstep driving. However, these methods don’t improve accuracy. Better angle-torque characteristics help reduce the impact of frictional loads, such as in ball screw applications. |

Â

Â

|

Option 2

|

Use an encoder type stepper motor for reliability. |

Â

Although a standard hybrid stepper motor won't miss steps if properly sized for the load and speed, modern automation systems demand greater reliability. Many designers now implement closed-loop feedback to ensure the motor doesn't lose steps during operation. Preventing missed steps is crucial because it can affect subsequent motion and other processes after the error occurs.

Â

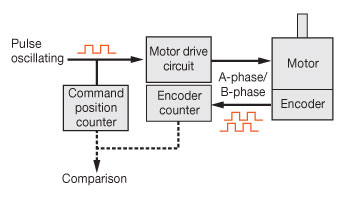

| By adding an encoder to the rear shaft of a stepper motor and closing the feedback loop to the controller, the motor's travel distance can be monitored and verified by comparing the commanded steps to the encoder pulses. If steps are missed, the system can automatically correct them to avoid delays. |  |

Â

|

|

Â

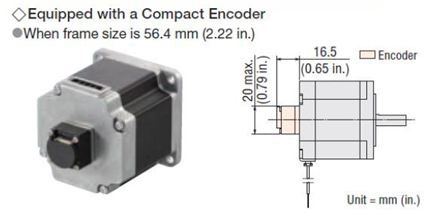

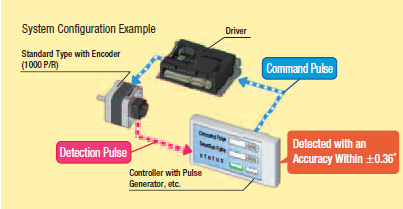

Many types of encoders are available and can be pre-assembled by Oriental Motor. For our PKP Series, compact incremental encoders with different resolutions, channel counts, output types, and electrical specifications are offered for maximum flexibility with host controllers or PLCs. For longer distances, use line driver output encoders to improve noise immunity.

Â

Encoder Specifications

|

Encoder Code |

R2E |

R2F |

R3J |

R2EL |

R2FL |

R3JL |

|

|

Type |

Incremental |

||||||

|

Resolution |

200 P/R |

400 P/R |

1000 P/R |

200 P/R |

400 P/R |

1000 P/R |

|

|

Output |

A-phase, B-phase, Z-phase (3ch) |

||||||

|

Input Current |

45 mA or less |

30 mA or less |

|||||

|

Input Voltage |

5 VDC ±10% |

||||||

|

Output Type |

Voltage (TTL equivalent) |

Line Driver |

|||||

|

Output Voltage |

Low |

0.5 VDC or less |

|||||

|

High |

4.3 VDC or more (with no load) |

2.5 VDC or more |

|||||

|

Response Frequency |

100 kHz |

200 kHz |

|||||

Â

|

Oriental Motor's PKP Series stepper motors are known for their quality and include both high-resolution and encoder types.

Watch another video to learn more about the PKP Series stepper motors, including its high torque design and other types.  The PKP Series offers 2-phase bipolar type (4 wire), 2-phase unipolar type (6 wire), and 5-phase bipolar type (5 wire) to connect to your preferred driver. Use a 5-phase motor for applications requiring lower vibration or noise.

|