Modular automation represents the next step in factory automation, where production lines can be divided into mobile modules and quickly reconfigured for different purposes. This article explores the benefits of modular automation and highlights how smaller, lighter, and battery-powered motors can support this approach.

Â

Â

In today's fast-paced manufacturing environment, there is an increasing need to respond rapidly to changes such as labor shortages, natural disasters, and supply chain disruptions. Many companies are turning to automation to improve efficiency and safety, especially in tasks like transporting parts or working in hazardous areas. Additionally, more businesses are exploring modularization to allow production lines to adapt to new requirements.

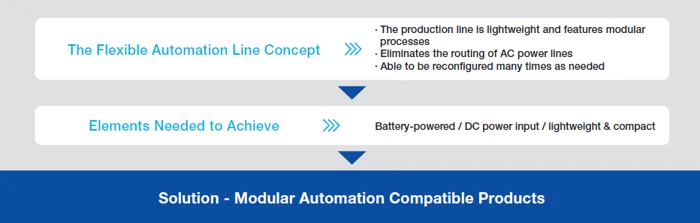

The key to overcoming these challenges lies in achieving "layout-free" automated equipment and production lines, which forms the foundation of "modular automation."

What is Modular Automation?

The term "modular" refers to components that can be rearranged to form a larger system. It can apply to production lines, manufacturing plants, or even products themselves.

Automation means performing tasks with minimal human intervention.

"Modular automation" is the next evolution in factory automation, allowing a production line to be divided into mobile modules that can be quickly reconfigured for different applications.

Imagine each module as a Lego piece on wheels—each carries equipment for a specific purpose and can easily connect with other modules. For example, a packaging line designed for apples could be adapted to package pineapples instead.

Â

By enabling the same production line to serve multiple needs, factories can respond instantly to changes in demand. The highest efficiency is achieved when all production equipment is modularized and powered by autonomous mobile robots that communicate wirelessly and are controlled by AI.

Â

Benefits of Modular Automation

The flexibility of repurposing a single production line for different processes can boost productivity while saving space, energy, and labor. This leads to greater cost savings, faster time-to-market, and reduced downtime.

Â

|

Benefits of Modular Automation: â— Free layout â— Productivity improvement â— High-mix low-volume production â— Resolving labor shortage â— Space-saving â— Energy-saving â— Cost-saving â— Faster time-to-market |

Helpful for Industries Requiring Small Batches: • Food & beverage • Chemicals • Pharmaceuticals • Medical • Textiles • Marine • Printing ◠Packaging |

Â

There are two main types of modular automation: semi-mobile and fully-mobile.

Â

Semi-Mobile Modular Automation

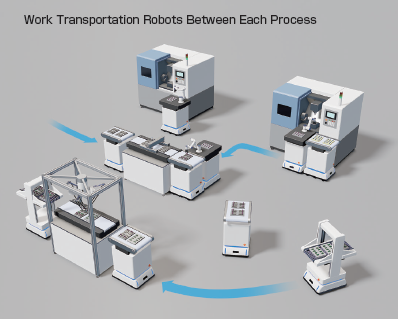

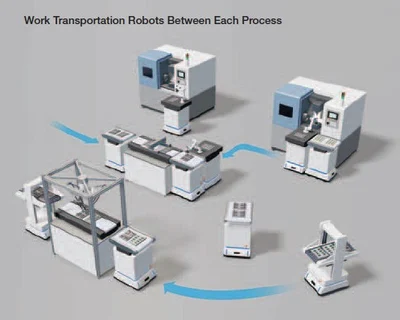

In semi-mobile modular automation, both fixed and modular components exist, and parts are automatically transported between modules using mobile robots.

Â

Â

Semi-mobile modular automation lines have certain modules fixed to the floor. However, by integrating mobile robots with conveyor modules, mobile parts transfer becomes possible, improving efficiency by eliminating manual part transfer between modules. A mobile robot with a small turning radius can operate in limited spaces, enhancing space utilization.

Â

Â

Fully-Mobile Modular Automation

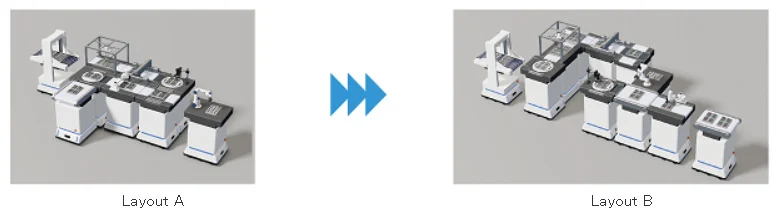

In fully-mobile modular automation, every module is powered by mobile robots, allowing each module to move and reconfigure itself automatically.

Â

From Layout A to Layout B

Â

By modularizing and mobilizing the entire production line, flexibility is maximized as more layouts can be customized for different needs.

Â

Â

The table below shows a comparison between "semi-mobile" and "fully-mobile" modular automation. The U-shaped line in "semi-mobile" modular automation is fixed and cannot be moved. As you can see, the modular production line method (fully-mobile) can be more flexible and even add additional units to meet more needs.

Â

|

Semi-Mobile

U-line+Modular production line |

Fully-Mobile

Modular production line

|

|---|---|

|

|

|

8 types 9 units

|

11 units of 8 types (2 units added due to line change)

|

|

Line flow

|

Line flow

|

| ①Lifting (parts loading) ② Parallel (parts mounted) ③ X-YZ (adhesive application) ④ Turntable (visual inspection) ⑤ Vertical articulated (machined parts mounted) ⑥ Cross roller conveyor (part orientation change) ⑦ Scalar (screw ) Tightening) ④ Turntable (changing the direction of parts) ⑧ Conveyor (carrying out parts) |

â‘ Lifting (parts loading)

â‘£ Turntable (parts orientation change) â‘¡Parallel (parts mounting )

â‘¥Cross roller conveyor (parts orientation change)

â‘¢X-YZ (adhesive application ) â‘¥Cross roller conveyor (parts orientation change)

④ Turntable (visual inspection) ⑧ Conveyor (parts transfer) ⑤ Vertical articulation (mounted with processed parts) ⑦ Scalar (screw tightening) ⑧ Conveyor (parts carry-out) |

Â

Support Modular Automation withÂ

Modular Automation Compatible Products

- For engineers looking to implement modular automation, it's best to consider battery-powered, smaller, lighter, and smarter motors and drivers. Standardizing on the same product technology for all axes of motion can also shorten the learning curve. Manufacturers have already begun offering products that fit the "modular" requirement.

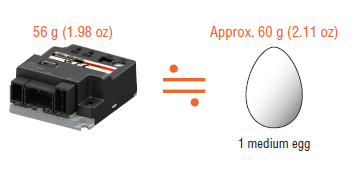

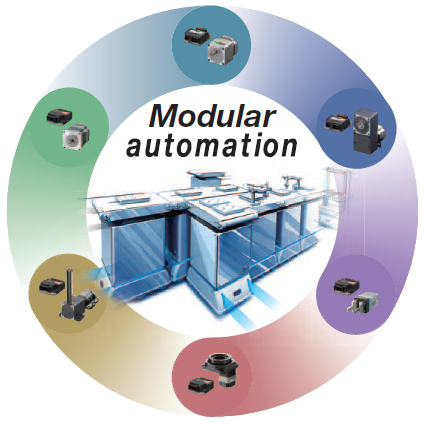

"Modular automation compatible products" are a group of products with the common concept of battery drive, small size, and lightweight. They are ideal for mounting on self-propelled devices and mobile equipment and contribute to the realization of modular automation. Similar to a "modular" production line, modular automation compatible motors, actuators, and drivers can also be mixed and matched for different purposes.

At this time, Oriental Motor's modular automation compatible products consist of the AlphaStep AZ Series family of DC-input stepper motors, linear actuators, hollow rotary actuators, and mini drivers as well as the BLV Series R Type DC-input brushless motors and drivers. Supported industrial communication protocols include EtherNet/IP, EtherCAT, Profinet, CANopen, Mechatrolink, CC-Link, SSCNetIII/H, and Modbus RTU.

Â

|

For Positioning: AZ Series Absolute Stepper Motors or Actuators with mini Driver Oriental Motor's AlphaStep product family is now equipped with a battery-less mechanical absolute encoder. In addition, the AZ Series mini driver has been designed to be small and lightweight, freeing up valuable cabinet space. Combine it with the wide product breadth of the AlphaStep AZ Series and related products.

|

||||||||

|

For Speed Control or Basic Positioning: BLV Series R Type Brushless Motor and Compact Driver Oriental Motor's BLV Series recently expanded to the "R Type", which includes a slimmer brushless motor and a much smaller driver that accepts battery power. Features and functions are kept from the original BLV Series, such as ramp operation and low battery operation.

|

Â

Pressureless Parts,Non Pressure Parts,Non Pressure Components,Non Pressure Component Parts

Jinan Boiler Group Co., Ltd. , https://www.jinanboiler.com