Gaskets are essential components that prevent the leakage of fluids and gases by creating a tight seal between two mating surfaces. From automotive engines to industrial machinery, plumbing systems, and even consumer products, gaskets ensure reliable performance under various conditions, including high pressure and temperature fluctuations. In this detailed guide, we explore the different types of gaskets, their applications, and how to choose the right one for your specific needs.

- What Is A Gasket?

- What Are The Types Of Gaskets?

- How To Select The Right Gasket?

- APG: Your Trusted Gasket Partner!

What is a Gasket?

A gasket is a mechanical seal designed to fill the gap between two or more surfaces, preventing the escape of gases or liquids. It's typically made from flexible materials like rubber, metal, or composite substances that can adapt to the shape of the surfaces it's sealing. This flexibility allows gaskets to maintain a strong, durable seal even in challenging environments.

Gaskets are widely used across industries, from automotive and aerospace to manufacturing and construction. They play a critical role in ensuring the integrity of systems where fluid or gas containment is vital. Whether it's an engine block, a pipe joint, or a valve, gaskets help maintain efficiency and safety.

What Are The Types Of Gaskets?

There are many types of gaskets, each designed for specific applications and operating conditions. Here are some of the most common ones:

-

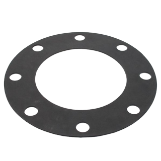

Flat Gaskets: These are simple, flat seals often made from rubber, cork, or metal. They are ideal for sealing flat surfaces and are commonly used in flanged connections.

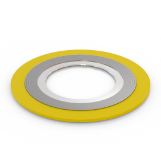

Spiral-Wound Gaskets: Made by winding a metal strip with a filler material in a spiral pattern, these gaskets are highly resistant to high pressure and temperature. They are commonly used in piping systems and flanged joints.

-

Custom Gaskets: Designed for unique or non-standard applications, custom gaskets are tailored to fit specific dimensions and requirements. They can be made from a variety of materials, including rubber, Teflon, and metals.

-

Ring Joint Gaskets (RJGs): These are used in high-pressure and high-temperature environments, such as in oil and gas pipelines. They are typically made from solid metal and are designed to withstand extreme conditions.

-

Composite Gaskets: Combining different materials, such as rubber and metal, these gaskets offer enhanced durability and versatility. They are often used in applications requiring both flexibility and strength.

How To Select The Right Gasket?

Selecting the correct gasket involves considering several factors, including the type of surfaces being sealed, the operating environment, and the media being contained. Key considerations include:

- Material Compatibility: The gasket material must be compatible with the fluid or gas it will be sealing, as well as the temperature and pressure levels.

- Surface Finish: The condition of the mating surfaces affects the performance of the gasket. Rough or uneven surfaces may require a different type of gasket than smooth ones.

- Application Requirements: Some applications demand high resistance to heat, chemicals, or mechanical stress, which influences the choice of gasket type and material.

- Cost and Availability: While performance is important, cost and ease of procurement should also be considered, especially for large-scale or ongoing projects.

APG: Your Trusted Gasket Partner!

At APG, we specialize in providing high-quality gaskets and sealing solutions tailored to meet the unique needs of our customers. With years of experience in the industry, we understand the importance of precision, durability, and reliability in every gasket we produce.

Our team of experts works closely with clients to identify the best gasket solutions for their applications. We offer a wide range of standard and custom gaskets, manufactured using advanced techniques and premium materials to ensure optimal performance in even the most demanding environments.

Whether you're working on a small project or a large-scale industrial system, we have the knowledge, technology, and commitment to deliver the perfect gasket solution for you. Let us help you achieve better performance, longer lifespan, and greater safety in your operations.

Contact us today to learn more about our gasket solutions!

Â

Â

hbspt.cta._relativeUrls=true;hbspt.cta.load(7315465, 'f2a2d2f0-0bfb-4d25-8045-9f84e0f46567', {"useNewLoader":"true","region":"na1"});

hbspt.cta._relativeUrls=true;hbspt.cta.load(7315465, 'f2a2d2f0-0bfb-4d25-8045-9f84e0f46567', {"useNewLoader":"true","region":"na1"});

Helical Gear,Right Angle Bevel Gear Reducer,Bevel Gear Spur Gear Ductile Iron,Forging Bevel Pinion Axle Bevel Gear

Taizhou Hongxiang Power Machinery Co.,Ltd , https://www.hxcamshaft.com