Understanding the Differences Between Oxyfuel Cutting and Plasma Cutting: Choosing the Best Option for Your Needs

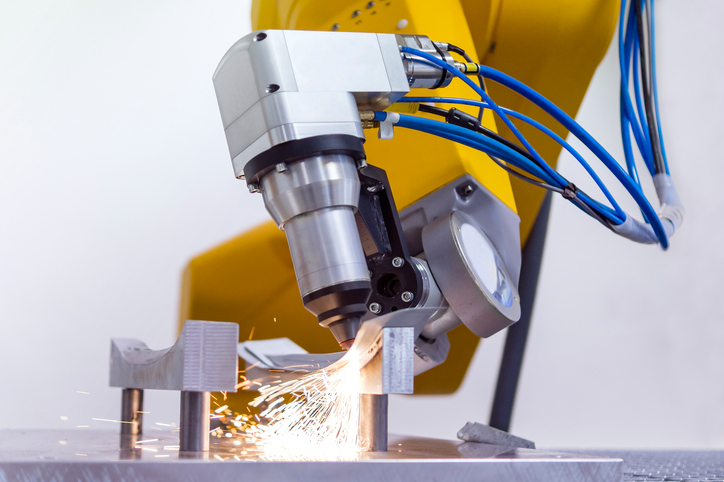

When it comes to automation in manufacturing, robotic cutting is a common and essential process. However, choosing between oxyfuel cutting and plasma cutting can be a challenge. Both methods have their own strengths and weaknesses, and the right choice depends on your specific application and material requirements.

Understanding the fundamental differences between these two cutting technologies can help you make an informed decision. Let’s explore how each method works, their advantages, and when they are most effective.

The Basics of Plasma Cutting and Oxyfuel Cutting

Plasma cutting uses a high-temperature ionized gas, known as plasma, to melt and cut through metal. This process involves passing an electric current through a gas (such as compressed air or nitrogen), which turns it into a plasma state. The plasma is then forced through a narrow nozzle at extremely high speeds, creating a concentrated heat source that melts the material and blows away the molten slag.

Oxyfuel cutting, on the other hand, relies on a mixture of oxygen and a fuel gas (like acetylene or propane) to preheat the metal to its ignition temperature. Once the metal is hot enough, a high-pressure oxygen jet is directed at the cut line, causing a chemical reaction that oxidizes the metal and removes it from the workpiece. This method is commonly used for cutting thick steel plates.

Advantages and Disadvantages of Each Method

Plasma cutting is known for its speed and precision, especially when working with thin metals like aluminum or stainless steel. It is ideal for applications where fast cuts and clean edges are required. However, plasma cutting may not be suitable for very thick materials, and it typically doesn’t work well with ferrous metals like carbon steel due to the risk of re-ignition.

Oxyfuel cutting, while slower than plasma, is highly effective for thicker materials, particularly those containing iron. It provides a smooth, consistent cut and is often preferred for heavy-duty industrial applications. However, it requires more time to complete a cut and is less efficient for thinner metals, which can lead to excessive heat distortion.

Each cutting method has its own set of benefits and limitations. While some applications may benefit from either technique, the best choice will depend on factors such as material type, thickness, desired cut quality, and production speed.

If you're trying to decide between oxyfuel and plasma cutting, consider your specific needs and consult with an expert in automated cutting systems. With the right approach, you can optimize your production process and achieve the best results for your business.

For more information about advanced robotic cutting solutions, including both oxyfuel and plasma systems, visit Genesis Systems Group today.

Posted in Robotic ApplicationsGravel And Sand Screen Machine

YK Series circular Vibrating Screen, also called vibrator screener machine, or vibratory screenig machine, can be used to separate minerals into various sizes for further processing in crusher. It incorporates a vibrator, eccentric block, mesh, spring, triangular belt and motor and is used for discharging bulky goods, sand, gravel, coal and coke from hopper to crusher. We can design and supply all ranges of vibrating screens according to the capacity and requirement.

The circular vibrating screen causes the motion trajectory to approximate a circle, so it is simply referred to as a circular vibrating screen. The circular vibrating screen is a multi-layer, high-efficiency new vibrating screen. The circular vibrating screen adopts the simplified eccentric shaft exciter and the eccentric block to adjust the amplitude. The material sieve has a long line and many screening specifications. It is widely used in product classification of mining, building materials, transportation, energy, chemical and other industries.

Gravel And Sand Screen Machine,Quarry Plant Vibrating Screen,Quarry Circular Vibrating Screen,Sand Gravel Vibrating Screen

henan ascend machinery , https://www.ascendminingcrusher.com